It's been a while since I wrote a post on the blog. There are several reasons, partly because I mostly dealt with repairs that had been left for too long, partly because I spent computer time cleaning up my hard drives and digitizing my cassette tapes. In the meantime, the work has still continued in the shop as usual, and I have two finished GammelGura to present eventually.

The most time-consuming project has been hunting down all the song lyrics I've done over the years. They have existed in about 50 PageMaker and InDesign files since the late 1990s, often as copies and containing hundreds of songs with chords. My mistake is not keeping everything in order over the years and keeping track of the latest version of all texts, which bites me now. In order not to lose anything good, each original file has been saved as a large PDF file with up to 200 pages, which was then split into one file per page/lyrics. The name of the files has since been changed to the date of the original file and the name of the song, each song has then received its own folder. After going through all the original files, each folder has between 5 and 30 versions of the lyrics and the number of folders/songs is just over 400, there are probably a few more to be found. It has taken its time!

My old cassette tapes, about 60 of them, have been digitized, and the large files have been cut up into pieces. Half of the tapes are unfinished ideas or the very first versions of finished songs in little snippets recorded on my little dicta phone. Good ideas have appeared that must become finished songs, but also almost finished forgotten songs. Some very early recordings from the early 1980s as well. Say what you will, the cassette tapes are lousy quality, but they're still around! I'll go through the sea of ideas with nonsense lyrics and traditional chord turns and refine what happens to be good, it's already become a new song from a good melody on the first tape that never got its lyrics.

For the past two weeks I have been floored by a bad cold. Not much was done apart from watching all the TV programs with gold diggers, crab fishermen, auctioneers, finders, renovators, treasure hunters, antique dealers etc. etc. However, I did managed to clean almost the whole apartment and replant the flowers as well. I got exhausted of watching TV whole days!

Yesterday was the first day I felt healthy enough to make it to the shop. About six months ago I invested in a mini lathe intended to be used to drill out centered holes for a 4 mm pearl dots in solid Waverly ebony pins. Old hand-made solid string pins from the 1930s and older are always made of wood, usually made of ebony, and with a significantly larger pearl dot than in modern string pins. The old original pins are often missing or are in too bad a condition. New pins are almost always needed, but new pins in the style of the old ones are not available for purchase.

I have tried different methods and jigs to drill the pearl dot, the problem is that it is extremely difficult to center the hole. A misalignment of a few tenths of a mm is enough for it to look crooked. I've gotten the best results by aiming with the eye and hoping for the best. But it was labor-intensive and in a batch of 60 pins there were always about ten pins where the dot ended up too crooked and one or two pins that broke, very few were perfectly centered. My intended solution to the problem had to be the mini-lathe. When I bought it, I already had a large stock of finished pins, only now it was time to try it in practice.

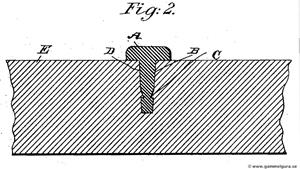

The lathe, one Proxxon Micromot DB 250, was supplemented with a large chuck and a small chuck. The principle is to attach a round oak rod to the large chuck that spins and use drills in the small fixed chuck to make a hole in the middle of the round oak rod into which the string pin can be pushed. With a 4 mm drill, the hole for the pearl dot can then be drilled centered in the string pin. After a bit of experimenting I found that the standard string pin reamer could not be used in the oak rod, the hole became off-centered. Only if I used a fairly large drill bit (5,3mm) did the string pin stay still when the lathe was running. Furthermore, I had to stiffen up the 4 mm drill with a sleeve of epoxy-glued birch so that it would not bend when I drilled. The sleeve was easily produced in the lathe. The slider with the drill was also a little loose, but I fixed that with a 0.3 mm feeler gauge.

By pushing the slider with the drill against the string pin, it was easy to drill the hole, the string pin could then be prayed free with small pliers. The lathe also had a stop for the slider, so I didn't drill the hole too deep or too shallow.

It felt a bit scary with the protruding jaws on the big chuck when the lathe was running, I'll make a guard before I use it next time!

The result was successful. Out of 60 pins, there were about 5 that were not quite perfectly centered, probably some of the first ones before I found the right method. It was much faster to make the pins and there is no risk of any pin breaking.

After gluing the pearl dots with number 20 Stewmac superglue and a little sanding of the top (the head of the pin is round and the dot flat) there are pins enough for the next 10 GammelGura. A cheap 5 degree reamer has been ordered, it will be butchered from the handle and allow a centered and tapered hole to be drilled in the oak bar instead of the straight 5,3 mm drill hole for a better fit to the string pin.

A protective guard was made from a piece of plastic pipe.